APAD MultiThe APAD Technology™ Multi device is an air pressure adjusting device that can be applied with a separate negative air machine(s) or in combination with other such air ventilation and flitration systems. To step into a new era of air cleaning using APAD Multi is easy as one does not need to invest in new negative air machines. APAD Multi creates and maintains an accurate negative pressure level, and reacts to any sudden changes in air pressure level. The device is equipped with automatic alarm system for too low negative air pressure, as well as with a data logging system. The alarm system shows and marks all alarms in the APAD control unit. The unit also has 2 pieces of external low voltage alarms that can be used with signal light or voice alarm. The APAD Multi data logging saves the pressure level and alarm data in a CSV-file format. The data can be exported to Microsoft Excel. The air pressure measuring unit can be removed from the APAD unit and moved further away by using an extension cable. This way the pressure measurement can always be applied between any two (2) different room spaces according to each need. The APAD Multi can be located inside or outside the containment. When the unit is located outside the containment the circulation air shall be returned to the contained area by attaching an air hose to the APAD air circulation opening and guiding the air back to the containment space. The APAD Technology can also be used for creating controlled excess air pressure.

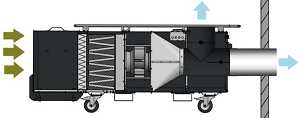

APAD indoor air quality systemThe APAD indoor air quality system has an integrated fan, coarse filter, HEPA H13 filter as well as a possibility for active coal filtering. So it is all in one pagkage. The system is typically used in cases where poluted air moves from space to another causing health issues or threath. For example these systems are found in school building basements or crawl spaces that have different harmfull odours in air, such as oil based residues, mold, VOC and so on. The system is installed to create a controlled negative pressure between poluted area and clean area. The effect is immediate after the system is started as poluted air doesn´t move from roomspace to another anymore. Also the poluted area indoor air quality improves after time as the particles and odours are filtered with high volume all the time. The system brings immediate results and is hugely cheaper to install and use than a large scale building renovation. And even though the building renovation would be the solution, rarely the work can start right away. The APAD system can be installed also as a temporate system untill the actual repair work starts. The system has optimized air flow and therefore the machine is sized bigger than common systems. The air is sucked in to an air chamber through suction pipes that are installed to suck in the poluted air from around the poluted roomspace or area. The pressure control unit is installed to monitor and control pressure level between poluted area and clean area. These basic systems as well as the system control unit etc. are same as in the APAD Multi.

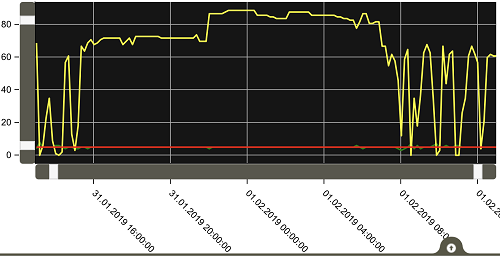

The indoor air quality APAD system is equipped also with remote monitoring and controlling. The system gives a possibility to adjust the desired pressure difference level remotely, but more importantly gives the data of current pressure level as well as history of it, air blade working info as well as current set pressure level, all in one table. This gives good info to users to understand how much there are different things causing pressure losses, and how well the APAD system can provide and upkeep the set negative pressure level, with accurate and sharp automatic controlling.

|

New era of energy friendly and safety improving negative pressure air cleaning technology